Bonanza Offer FLAT 20% off & $20 sign up bonus Order Now

In the past, the apparel industry operated on push model but today with new entrants and stiff competition, the apparel brands are being forced to come up with innovative products to meet the customer expectations. A brand needs to cater different market segments created on the basis of geography, demography, and lifestyle. For example, a brand has to keep in mind that geographical locations differ on the basis of style, requirements, per capita income, taste etc. Thus the same product cannot serve different geographical locations.

Zara is a retail giant that deals in clothing and accessories. It was founded in 1975 and is headquartered in Arteixo, Spain. It has over 2000 retail stores spread across 88 countries. Zara is a subsidiary of Inditex, world’s largest retailer in apparels. Zara has established its leadership in the apparel industry. Zara has been accepted as an affordable and fashion forward brand by the customers across the globe. Zara’s well-managed supply chain strategies have made it a highly profitable company (Caro et al., 2010). Zara believes in spending money on opening new retail outlets and increasing its reach rather than spending on advertisements/ promotional campaigns. Since the apparels manufactured by Zara are unique, it encourages people to visit its stores to experience the fashionable clothes rather than buying the clothes online.

A majority of the products are manufactured in Spain. If the sales for a design are not encouraging in a particular geographical location, the product is withdrawn from the retail outlets of that location and new designs are pursued. Zara’s ability to match customer preferences results in the sale of the majority of products at full price (Caro et al., 2010). The retail giant has invested a lot of money in the information system in order to have access to latest sales related data. All these operational strategies help Zara to build a strong customer base, gain profits and achieve an edge over its competitors.

The main objective of this report is to analyze the effectiveness of decision making, supply chain management and logistics for Zara and make recommendations so that the company can maintain its competitive advantage.

Zara uses PEST (Political Economic Socio-cultural Technological) analysis to analyze the external environmental factors impacting its business. PEST analysis includes the following factors:

Political factors- These factors include the attitude of government towards people, the level of democracy and political stability within a country. Zara should know the trade rules, regulations related to import/ export, tax-related government interventions and political situation of the country it operates in. This will prevent disruption or unnecessary closure of the business in a particular country (Guan and Zhang, 2011).

Economic factors- These factors include the income distribution, economic condition of different segments of the population, purchasing power, rate of growth of the economy, inflation rate, exchange rate etc. Since the income distribution is uneven, the lower segment of the population cannot afford premium and luxury products. Zara should price its products while keeping in mind the per capita income and purchasing power of the target customers (Guan and Zhang, 2011)It should decide profit margins on the basis of economic factors.

Socio- cultural factors- These factors include the perception of people towards themselves, traditions, beliefs, lifestyle of people and level of education. People are becoming conscious of their lifestyle and the brands they wear (Guan and Zhang, 2011). People are becoming aware of what is happening in other parts of the word in terms of fashion. Zara should be familiar with the spending habits of the target customers.

Technological factors- These factors include the amount of money spent on Research and Development, the rate at which innovations are happening and pace at which technological changes are being accepted. Internet penetration is increasing and online marketing is gaining pace. Technological changes help Zara in quality control. Social media helps Zara to stay connected with its customers (Gamboa and Gonçalves, 2014).

Following are the five basic steps involved in Supply Chain Management:

Planning- Certain metrics are defined in order to monitor the efficiency of Supply Chain Management and maintain the quality of products delivered to the customers.

Sourcing- Choice of the supplier should be made carefully. A supplier should be chosen who delivers quality raw materials without any delay and at a reasonable price.

Making- This stage involves manufacturing of goods. A proper schedule needs to be made for production, packaging and delivery of goods (Hoole, 2005).

Delivering- A proper network of warehouses and distributors needs to be maintained. There has to be a proper invoicing mechanism for collection of payments.

Returning- A company needs to maintain a proper mechanism for the return of defective or sub-standard goods.

Following are the elements of production planning and control considered by Zara:

Materials- Raw materials and finished goods should be readily available at the required time and required quantity. The procurement of raw material, delivery dates of materials according to specifications and standardization of products should be taken care of for uninterrupted production.

Machinery and equipment- This include deciding the schedules for production, procurement of machines/ equipment, their maintenance and downtime of machinery. It is the responsibility of the management to ensured that there is minimum downtime of machinery due to the breakdown or technical faults.

Routing- It is concerned with deciding a path/route that should be used for the transforming the raw materials into finished goods ready to be used by consumers. A layout needs to be prepared for the sequence of operations that needs to be undertaken. An analysis is done regarding the quantity and specifications of materials that should be used for production of finished goods (Hyojung and kwon, 2013). Each operation is defined in detail and process time is decided for each operation.

Loading and scheduling- Date and time are decided for the commencement and completion of each operation. A plan is prepared that includes material requirements, manpower requirements and machine time so that the operations for apparel manufacturing can be completed within given timelines. The loading of machines/ equipment is done depending upon their capacity.

Dispatching- In this stage necessary orders and instructions are issued. It marks the commencement of production activities. Raw materials with required specifications are issued to different processes and work related instructions are issued to workers.

Inspection and follow up- Inspections are done to ensure that the quality standards defined by an organization are being met for the products delivered to their customers. It is carried out at different stages of production. The machines and equipment used for production and designing of apparels may also be inspected.

Zara and Dell are successful organizations where Zara manufactures apparels and Dell deals with manufacturing of computers. Zara has a vertically integrated supply chain whereas Dell has a virtually integrated supply chain. Dell buys spare parts from other firms and assembles them (Flores, 2010). Dell’s relationship with those firms is more binding than the traditional supplier-buyer relationship. The majority of the Dell suppliers are located very close to the assembly line of Dell. This helps Dell to operate on Just In Time basis. Dell uses Make-to-order strategy where all the hardware and software configurations are done on customer’s request. The customized computer is then delivered to the customer. The range of customized products is listed on Dell’s website. Since the inventory cycle for Dell is very small, the negligible cost is incurred on warehousing whereas, Zara relies on a network of warehouses for storage and distribution of apparels. Zara has a centralized distribution system. The entire production of apparels is shipped to the central location i.e. Spain. From Spain, the apparels are distributed to different countries on the basis of requirement of each retail outlet.

Myer does not segment the market on the basis of demography, values, lifestyle or buying behavior of customers, whereas Zara segments the market on the basis of demography and lifestyle. Myer has no set target audience, whereas Zara targets customers in the age group of 20-35 years. Myer makes use of discounts to attract the customers, whereas Zara attracts customers by using innovation and customer centric approach. This helps in building customer loyalty for Zara (Gamboa and Gonçalves, 2014).

The similarity between Zara, Dell and Myer is the use of Just In Time strategy and production of goods in small batches. Other companies can also adopt this strategy for better inventory management. Inventory includes raw materials, products whose work is in progress and finished goods that are ready to be sold. Every organization wants to fulfill the demands of the customers by providing quality products but it is equally important for an organization to have a smooth production process and minimize wastage (Columbus, 2014). Thus JIT will help the organizations to have the right design of products in the right quantity at the right outlet.

The not so successful companies like DoneByNone, Zomato, American Apparel, Pacific Sunwear and Urban Outfitters can also adopt the supply chain management strategies and minimize their inventory cost in order to increase their market presence and profitability. Just like Zara, these companies should work on improving their operations, promotional techniques and internal processes related to decision-making.

Logistics management is a component of supply chain management that involves planning, implementing and controlling the forward and reverse flow of information, goods, and services. The logistics involved in an organization include the flow of information, inventory of goods, production, packaging, warehousing and distribution of goods. Organizations use logistic management and supply chain management to meet customer expectations. Inbound logistics is concerned with the flow of goods into the organization i.e. from the suppliers to the company warehouse whereas outbound logistics is concerned with the flow of goods out of the organization i.e. from the company warehouse to the end customers.

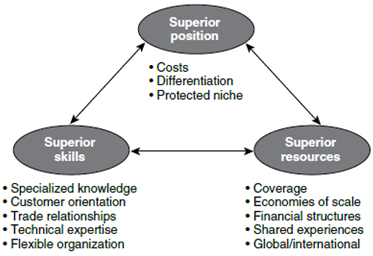

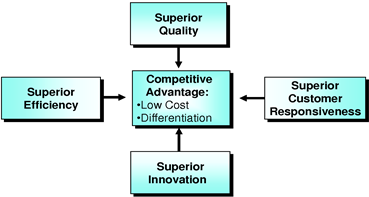

In today’s competitive world, organizations make strategic moves to gain advantages over their competitors. For this, the organizations try to gain leadership in terms of customer experience, pricing of goods/ services, innovation, quality of goods/ services etc. Competitive advantage is based on the strengths specific to the organization like workforce management, execution of manufacturing processes, technology etc. which lead to increased productivity, reduced costs and superior product quality. Resources and capabilities are the two factors that give rise to competitive advantage.

Figure 1: Sources of competitive advantage

Competitive advantage, in turn, leads to increased profitability. Following are the activities that enhance value creation for the customers:

Logistics- It controls the flow of goods from procurement of raw materials from the suppliers to the distribution of finished goods. Zara and Dell have efficient logistic systems that help in reducing the inventory costs (Kang and Johnson, 2011).

Human Resource- HR department is responsible for hiring, training and motivating the employees of an organization and create a positive work environment. This helps in enhancing the productivity of employees and improving customer services.

Information system- Electronic systems are used by organizations to keep a check on inventory, tracking target versus sales of products and dealing with customer responses/ inquiries. Zara, Dell, and other successful organizations rely on strong information systems (Kang and Johnson, 2011).

Infrastructure- An organization’s infrastructure includes a communication system, transportation system, manufacturing tools/ machinery etc.

Figure 2: Building blocks of competitive advantage

In order to improve its efficiency and effectiveness, Zara should choose its suppliers very meticulously. Selection of the supplier should be made keeping in mind the reputation of the supplier, the quality, specifications and grade of raw materials he supplies and the flexibility in supply scheduled in case the company wants to up-scale its production due to rise in demand. There should be no overlapping of information exchange within the organization or with external agents. Exchange of information should be done in a systematic and structured way so that there is no ambiguity or confusion. Proper schedules should be prepared for manufacturing, packaging and delivery in order to avoid delays or last-minute hassles (Tetteh and Burn, 2001). Senior management should take decisions regarding long-term targets for Zara and promotional activities while keeping the target audience and competitive environment in mind.

Zara should have a proper mechanism for quality checks for all the goods before they are transported to their final destinations. This will certainly help the company to keep a check on return flow of goods due to a defect or flaw in the product.

Companies try to optimize the production of goods and deployment of inventory on the basis of demand forecasting. Most forecasting tools are based on the assumption that demand can be predicted on the basis of past trends for all geographical regions and all product lines. This approach fails to analyze the impact of various demand drivers (Migrant and Cotton,2014) The sales force and managers provide a very optimistic forecast thus resulting in more inventories. Thus there is always an element of uncertainty associated with these forecasting techniques.

Since changes may be required in the design of products due to customer feedback or changes may be introduced in the marketing strategies etc., the tools selected for demand forecast should consider the variable factors and take into account the variations required on the basis of geography. Thus it is very important for a company to have a constant flow of information which includes sales related data and a strong forecasting tool.

Better forecasting, production planning and inventory management will lead to optimization of requirement of raw materials/ goods in progress/ finished products and their deployment. Thus Zara can reduce the wastage levels due to spoilage of inventory. It will also reduce last-minute modifications, chaos and stock-outs.

At Zara, a leading apparel company, the speed of introducing new product collections and responsiveness to changing fashions/ customer demands are given more importance than costing of products. The brand is known for introducing new apparel designs quickly. Zara ensures that the latest designs reach the stores while the trend is still at the peak and at the top of customer’s wish-list. This helps to create exclusiveness (Tetteh and Burn, 2001). Store managers at Zara retail outlets order new clothes that are delivered twice a week to the stores. For Zara, supply chain management provides a competitive advantage over other brands like Pepe Jeans, Sisley, The Gap and Benetton.

The company follows the strategy of Just In Time (JIT), which helps in reducing inventory cost and increasing efficiency. The company uses models for inventory optimization and ensures that limited stock is delivered to each retail outlet to keep a check on unsold inventory. The company does not produce in large lot sizes to attain economies of scale. Small batch productions help Zara to understand the acceptance of designs in the market. The company has a strong distribution network in order to make its presence felt in different continents of the world. The retail giant relies on in-house production and reserves a significant amount of capacity for adjustments in demand. This gives Zara the flexibility in the quantity and variety of producing new products. It relies on quality raw materials and sophisticated designing techniques. Zara has excellent human resource management (Bachrach And Bendoly, 2011). It offers lucrative salary packages and other benefits to its employees which result in higher productivity and efficiency. For improving customer experience, store managers take customer feedback on a regular basis regarding their likes and dislikes. The feedback is then routed to Zara’s designers who modify the designs/ color patterns according to the feedback.

The meticulous operational strategies, value creation for stakeholders and supply chain management can be credited for the success of Zara in comparison to other success apparel brands like Benetton, Esprit, Lacoste, Burton, Diesel, Van Heusen, Wrangler etc. and in comparison, to unsuccessful companies like DoneByNone, Zomato, American Apparel, Pacific Sunwear etc.

Bachrach, d. And bendoly, e. (2011). Rigor in behavioral experiments: a basic primer for supply chain management researchers. Journal of Supply Chain Management, 47(3), pp.5-8.

Caro, F., Gallien, J., Díaz, M., García, J., Corredoira, J., Montes, M., Ramos, J. and Correa, J. (2010). Zara Uses Operations Research to Reengineer Its Global Distribution Process. Interfaces, 40(1), pp.71-84.

Columbus, L. (2014). Five Strategies for Improving Aerospace Supply Chain Quality Management and Performance. SAE Int. J. Aerosp., 7(1), pp.142-145.

Columbus, L. (2014). Five Strategies for Improving Aerospace Supply Chain Quality Management and Performance. SAE Int. J. Aerosp., 7(1), pp.142-145.

Flores, R. (2010). Enrique Badia. Zara and her Sisters: The Story of the World's Largest Clothing Retailer. Enterprise and Society, 11(2), pp.432-433.

Gamboa, A. and Gonçalves, H. (2014). Customer loyalty through social networks: Lessons from Zara on Facebook. Business Horizons, 57(6), pp.709-717.

Gonzalez-Loureiro, M., Dabic, M. and Kiessling, T. (2015). Supply chain management as the key to a firm’s strategy in the global marketplace. International Journal of Physical Distribution & Logistics Management, 45(1/2), pp.159-181.

Guan, J. and Zhang, G. (2011). ZARA-Based Design Management. KEM, 474-476, pp.1447-1450.

Hoole, R. (2005). Five ways to simplify your supply chain. Supply Chain Management: An International Journal, 10(1), pp.3-6.

Hyojung Kim, and Ki Hoon Kwon, (2013). An Case Analysis of Entry in Global Fashion Market : Case of Zara and Uniqlo. International Commerce and Information Review, 15(4), pp.509-532.

Kang, M. and Johnson, K. (2011). Retail Therapy: Scale Development. Clothing and Textiles Research Journal, 29(1), pp.3-19.

Mo, Z. (2015). Internationalization Process of Fast Fashion Retailers: Evidence of H&M and Zara.IJBM, 10(3).

Smallbusiness.chron.com. (2016). Strategic Moves to Build a Competitive Advantage. [online] Available at: http://smallbusiness.chron.com/strategic-moves-build-competitive-advantage-21952.html [Accessed 14 Aug. 2016].

Tetteh, E. and Burn, J. (2001). Global strategies for SMe?business: applying the SMALL framework.Logistics Information Mngt, 14(1/2), pp.171-180.

Migrant-young, and Kim cotton, (2014). Customer-driven Design Management Strategy Of SPA Fashion Brand Focusing on H&M & Zara. journalofkoreadesignforum, null(45), pp.287-298.

The No. 1 assignment writing help provider in the United Kingdom, MyAssignmentHelp.co.uk is now better than ever. With the custom assignment writing services, 24x7 online support and 4000+ in-house PhD writers MyAssignmentHelp.co.uk now offers you unparalleled assignment help which will not only save you from hours of hard work but will also ensure you achieve the academic milestones which you have always dreamt of.

Upload your Assignment and improve Your Grade

Boost Grades